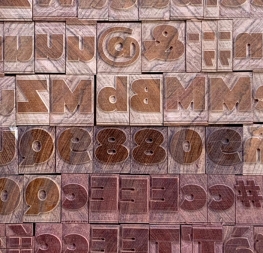

After this presentation, Veronika Burian of TypeTogether type foundry showed interest in the project. She mentioned that she was working on a project that had a lot to do with wood type and about her wish to see that project cut in wood. Time passed and in 2020 José Scaglione got in touch with us inquiring about the possibility of cutting a version of TypeTogether’s Catalpa typeface in wood.

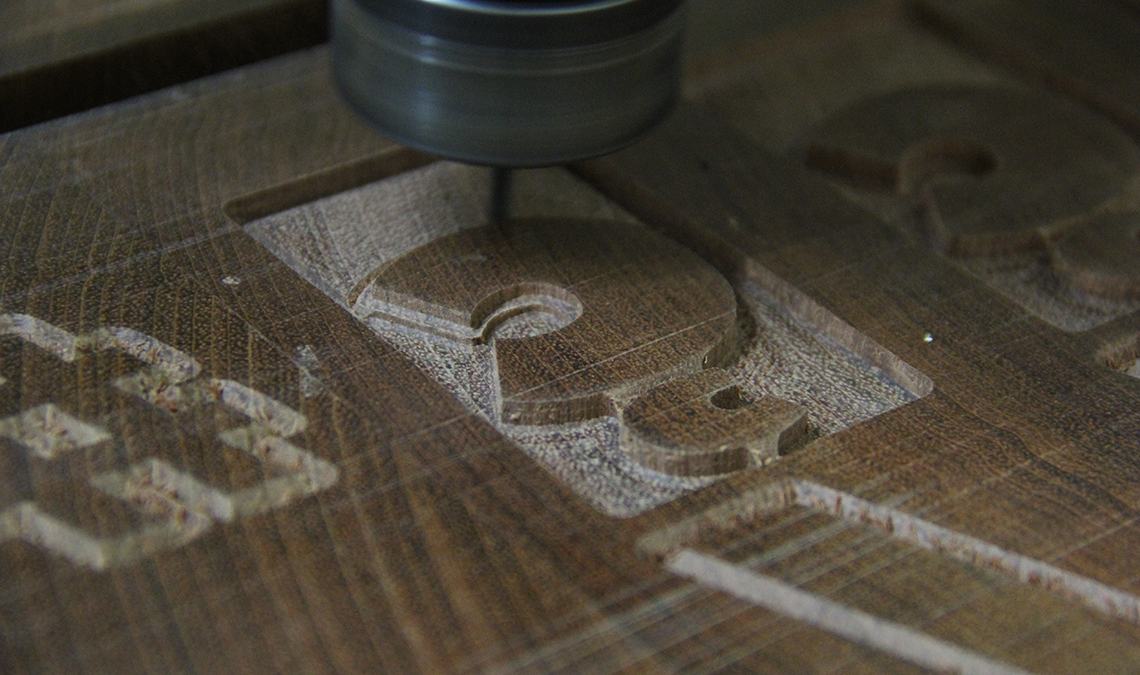

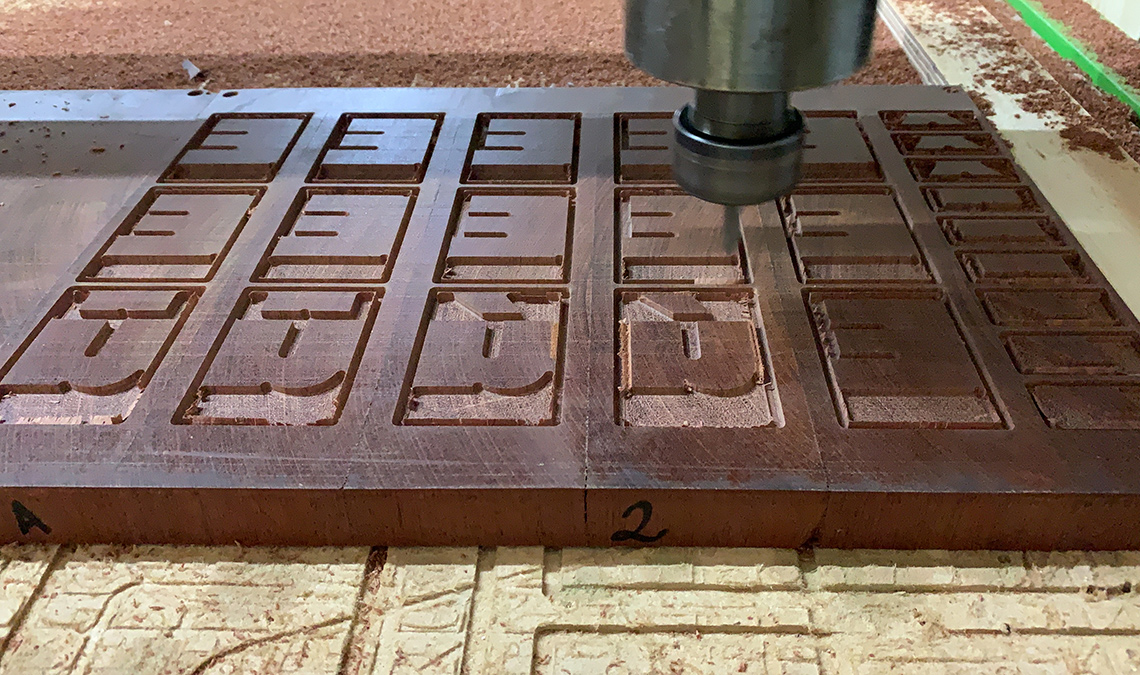

This is when Nícolas Loiola Camargo, a brilliant designer and skilled carpenter, joined the project. For his postgrad degree project at SENAC, São Paulo, he developed the Ibirapitanga type family, from its inception as a digital font to its materialisation as wood type. With Nícolas aboard, the group joined forces to produce the third generation of wood types.

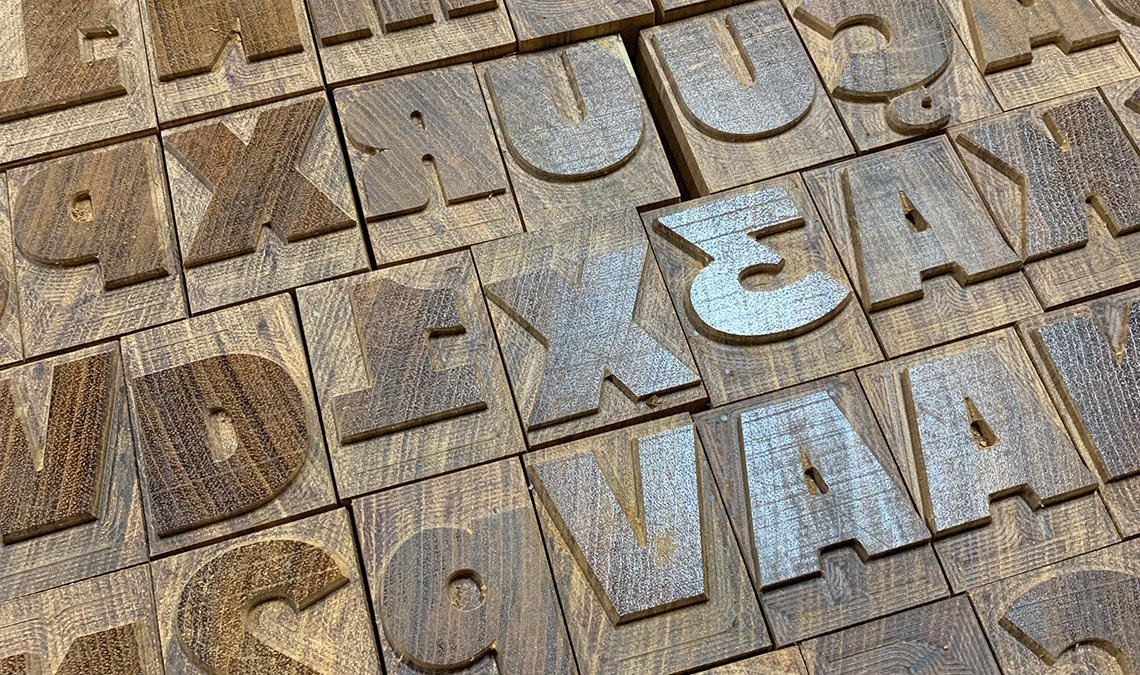

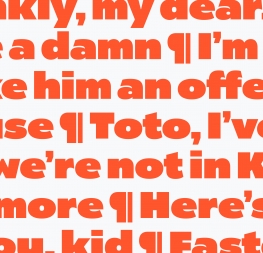

The final result is a wood type version of Catalpa Extrabold. The font contains more than 400 characters: uppercase and lowercase letters, numerals, a basic set of symbols and punctuation marks, and some accented characters. With this character set it is possible to compose texts in Portuguese, Spanish, or English.

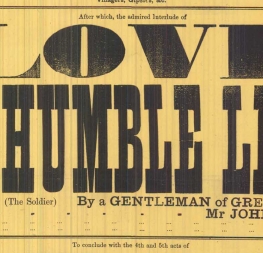

The project would not be complete without the development of a printed specimen — a poster (colourway one and colourway two). The idea for the poster was to work with something related to wood, trees, and forests. After all, Catalpa is also the name of a tree. The fragment of the text used on the poster, The stronger the wind, the stronger the trees, comes from the poem “Good timber” by American poet Douglas Malloch.

After some digital layout tests, the famous type designer Cláudio Rocha made some prints with the actual types. We unfortunately realised many of the characters needed to be replaced due to a host of reasons: milling and finishing problems, baseline alignment, damaged sorts, and other issues. Once we corrected the hands-on difficulties of dealing with wood type and were more careful in the production process, Rafael Neder printed the final version of the poster at Tipografia Matias print shop in Belo Horizonte, Brazil with the help of the master printer himself, Ademir Matias.